Attach the Snaps Easily !

TIPS & TRICKS

This page also explains common problems with fastening and how to solve them. Useful for those who are beginners or who want to know more tips about using the snaps-fit tool kit.

The Colorsnaps patented tool is an innovative product that uses combined components for installation. This is a flexible tool you may never see in the market. Although this is a simple mechanism theory operation, you need to understand two operational knowledge.

This is one of the most noteworthy tips. This tool is directly penetrates the middle hole panel and the front top panel through the stand and combines them together. When operating, the upper die of the top panel may not be able to be inserted into the front hole of the hole panel, or the front top panel may swing, which causes the button to shift during assembly.

The solution is that as long as you pay attention to whether the middle board and the front panel are aligned with the center during operation, this problem can be solved.

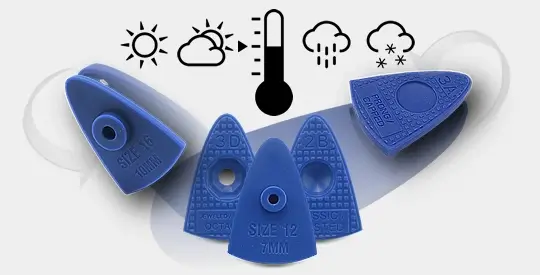

The tool is made of plastic "polycarbonate (PC)". When the die is inserted into the mold holder, the effect of tightness or looseness may occur. If this happens, it is the shrinkage and expansion of the material due to changes in weather conditions.

Please note that this rarely happens unless the temperature difference changes significantly.

There are many ways to influence the result of fastening the button. The following content mainly explains what may happen when using our snap attachment tool to install a snap set.

The embedded pearl snap button is made of Plastic or Synthetic Resin, and may easily break under the action of improper hammering force (Eg, Pearl and O-ring Snaps, please refer to the picture).

Therefore, we recommend that you try some of the best hammering forces before fastening. Regardless of any metal or non-metal button surface, please do not use the maximum percussion force to tap the top panel at a time during operation.

There is no doubt that long prongs are better than short prongs. But in fact, the best prong length should be measured according to the thickness of the material. Instead of just relying on "Longer Length" to solve the problem.

For example, the use of long prongs may cause Socket or Duo Stud to appear in the five protruding points of the thin fabric layer.

Why are there five points? Because after inserting the pins into the socket or Duo Stud groove, they will not bend properly. The result is that dots appear on the surfaces of both components. This is because the length of the prong is too long.

Solution : You can use the example on the left to find the best pin length. After the prongs penetrate the fabric, approximately 40% of their length will remain on the surface. Within this range, you can decide whether to use short or long prongs. To check whether the parts fall off easily, use your nails to pull the studs and the edge of the socket. This experiment can prove that it is firmly connected between the parts.